Remanufactured Volvo Penta Engines

Overview

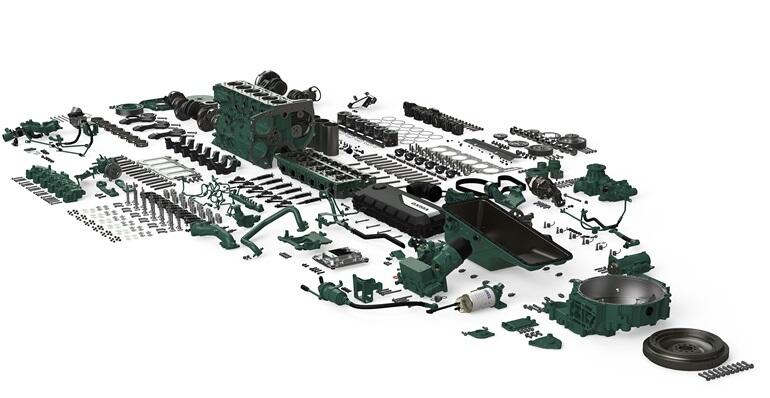

A lot of engine manufacturers offer remanufacturing services. This is how the process works under the Volvo Penta Reman Components system when it comes to off-road applications.

When a customer experiences an engine failure, they have the option of exchanging it for a remanufactured engine. They simply take it to their Volvo Penta dealership and will often receive the remanufactured engine the very next day. Meanwhile the old engine core is then sent for disassembly, where it is taken apart and each component is thoroughly inspected. If the engine can be remanufactured, it is sent to a remanufacturing facility. There, the components are restored or replaced, depending on their condition. All re-used or restored components must fulfill the same specifications as a new part. Parts that cannot be restored are recycled.

Once all components have been restored or replaced, everything goes back into the assembly line. The remanufactured engine then undergoes extensive testing to ensure it meets the original specifications and standards. It is then sent to the warehouse and eventually exchanged for another customer’s broken engine, where the whole cycle starts again.

“When the remanufactured engine leaves the remanufacturing facility, it is literally as good as new,” says David Hedin, Global Product Manager, Volvo Penta. “This means that it comes with the same warranty, and has the same expected lifespan, as any new spare part.”

Save time and money

In fact, the only real difference is the cost and delivery times. For engines that are no longer in production, the saving can be up to 30 percent. And while ordering a new engine can take around 8-10 weeks for delivery, a remanufactured engine can often be provided the very next day.

“Having such short lead times is where a remanufactured engine can really make a difference to your total cost of ownership,” explains David Hedin. “It also offers a lot of long-term security since even if we have stopped producing an engine, you can still access remanufactured engines for a long time ahead.”

Good for the environment

Since it is essentially recycling, remanufacturing has sustainability benefits too, and is in line with the principles of a circular economy. Even the engines and components that cannot be remanufactured are recycled for their raw materials.

More engines, more locations

Volvo Penta’s remanufactured engines have traditionally been offered in the form of longblocks, which contain just the base engine. While this is still an option, increasingly Volvo Penta can also offer complete engines that include all the major components needed to mount the engine. The result is faster and easier installation when it comes to swapping old engines for new. For off-road applications, this offer is available for the D5, D8, D11, D13 and D16 engines

Volvo Penta currently has remanufacturing facilities in France, Belgium, Sweden, Australia and the United States, and plans to open additional sites around the world, such as China. However, remanufactured engines and components are available to customers in all countries, other than those with specific import restrictions that do not allow it.

As mentioned, the speed of remanufacturing is a key reason for the lower cost. Even if engines and components can usually be delivered in all countries, having a remanufacturing facility in your vicinity can help decrease lead times and increase the chances of getting a new engine the next day instead of waiting for weeks. This means that you should take a good look at an engine supplier’s remanufacturing facilities before making a decision.